Acoustic Bass Guitar Case

Quick links:

Materials

Trapezoid = corners <> 90 degrees

Cutting plywood pieces

Commence construction

Hinge and latch cutouts

Making the heel-barrier

Starting the neck-support piece

Starting on the cushions

Completing the neck-support piece

Lid cushions

Final steps

Overview:

There are no commercially available cases or gig bags that will fit my acoustic bass guitars

Length |

1240 |

49" |

Lower bout |

460 |

18" |

Depth |

155 |

6" |

This trapezoidal case is rough'n'ready, a little heavy at 13.3kg, but should give good protection.

Since I can't buy materials and components in bulk, it's not exactly cheap. There's also lots of

hard, sharp edges that dream of damaging your guitar in a way that a gig-bag, or even a fully-lined

bent-plywood case wouldn't, but if you're careful loading and unloading you should be able to avoid

those kind of disasters.

Trapezoidal bass flight-like case, design scribblings

Need to be adjusted to acommodate thickness of plywood & foam

Initial sketch |

Measured |

(interior dims, 25mm clearance) |

|

overall length: |

1270 |

~1255 |

(1253 from Pythagorus) |

width at body-end: |

560 |

570 |

|

width at headstock-end: |

160 |

160 |

|

side length: |

1286 |

1270 |

|

depth: |

215 |

(20mm clearance at bottom, 40 at top) |

|

deviation angle: |

8.95 |

9.21 |

|

body-end angle: |

81.05 |

80.79 |

|

headstock-end angle: |

98.95 |

99.21 |

this seems to work for my basses having 160mm body depth at deepest point

use the body-thickness "calipers" jig - gently - to make sure bass is approximately this thick

Deviation angle calculation (after measuring)

body_width - headstock_width: |

410 |

half that ("rise") |

205 |

hypotenuse |

1270 |

"run" (Pythagorus) |

1253 |

rise / run |

0.1636 |

arctan (radians) |

0.16076 |

degrees |

9.21 |

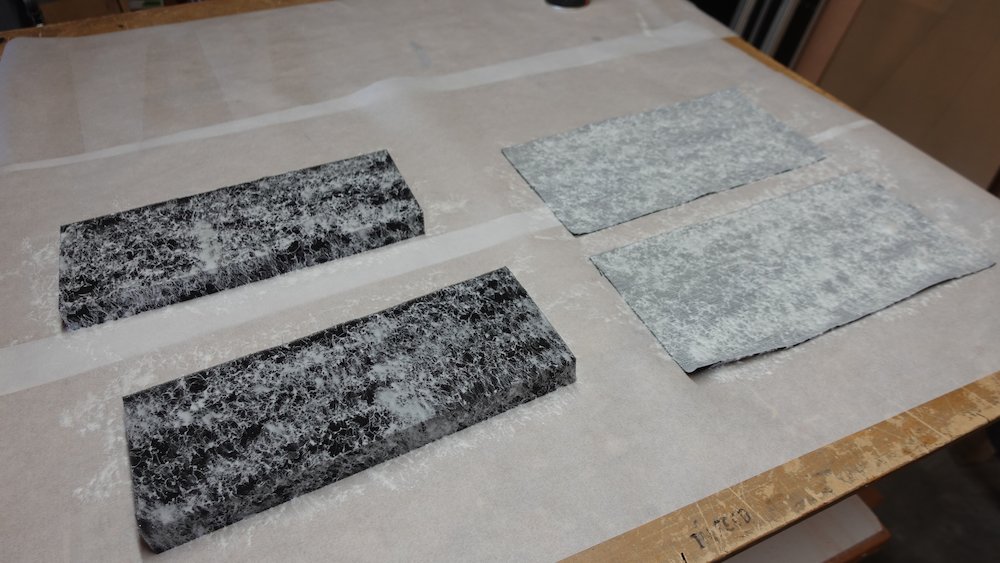

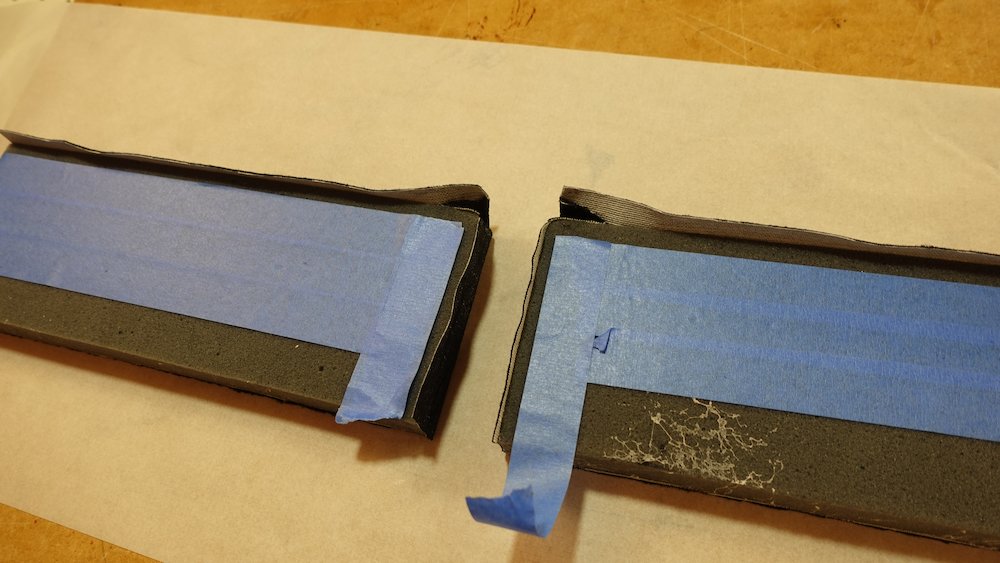

"Discrete" foam inserts / components

Stiff grey foam

29-400, available in 25/50/75/100, quite expensive

Softer black foam

"fuel filter foam" (can be ordered from Titan AV, cheaper)

Fat = 50mm

Thin = 25mm

Heel-barrier (stops body from moving towards headsock end)

Neck cradle (supports neck pushing upward_

Fat bottom (on bottom, across heel, part of upper bout)

Thin bottom (on bottom, across rest of body)

2x Fat sides (on sides, at upper bout / waist)

2x Thin sides (on sides, at lower bout)

2x Thin ends (on end-side, split for benefit of strap button)

3x Fat top (on lid, two along each side of body, one at end past bridge)

Thin top (on lid, along middle, bridge to nut)

Materials

Current working approach: double angle joiner extrusion

6mm / 0.25" plywood to keep weight down

Angle channels mean sides stop before the corner ("symmetrical" corners rather than butt joints)

With this hardware each piece needs to be 3mm LESS than the target interior dimension

(1.5mm offset in joiner cross section)

Rather than building the carcase and then cutting the lid off,

We'll build box and lid separately.

The hardware for this build, square-interior hybrid tongue-and-groove channel adds 6mm to height

5mm at "outer overhang" side (lid)

1mm at "outer bevel" side (box)

NB: double-check all of these, part numbers / options etc.

Supplier |

No |

Part |

Description |

Penn Elcom |

2* |

L978/928SMOL3 |

Medium SMOL3 Recessed Latch in Deep Dish with 22mm Offset |

Penn Elcom |

4* |

L0906 |

Backplate for Medium Recessed Latches |

Penn Elcom |

1* |

H7159EZ |

Heavy Duty Medium Zinc Recessed Handle with Rivet Protection |

Penn Elcom |

1* |

H1906 |

Backplate for Medium Recessed Handles |

Penn Elcom |

3* |

P2598Z(P2597Z) |

Medium Lid Stay in 7mm Deep Dish with 30mm Offset (prefer smaller offset) |

Penn Elcom |

2* |

E0885-2M |

6.8mm Double Angle Extrusion with 30mm Legs - 4m Long (prefer 4* 2m Long) |

Penn Elcom |

8* |

B1128/01 |

6 Hole PennBrite Brace with Offset 51.5mm x 42mm |

Armour |

2* |

EH6 |

ALUMINIUM HYBRID EDGE EXTRUSION, 6MM GAP |

Titan AV |

5* |

SKU: RC-SP-RIVET5-18S |

5x18 Aluminium Rivet & Washer, Silver, 100pcs |

Trapezoid = corners <> 90 degrees

Using the spreader and smoosher anvils, hammer and corner punches, bludgeon the hardware pieces into submission.

These jigs take a corner-piece, or length of corner-joining section, and adjust the angles.

The spreader fits inside a 90-degree angle, and by way of hammering the outside, spreads it to 99 degrees

The spreader allows a 90-degree angle to nestle inside it, and with a series of punches, compresses it to 81 degrees

The spreader jig |

The smoosher jig |

Cutting plywood pieces

Trace two copies of trapezoid from (oversize) MDF template onto 6mm ply sheet

Do not cut this outline: this is the target exterior.

Adjust sizes by drawing lines parallel to template outline

(Trim template in future so this is not necessary?)

For a target interior body length of 1260mm, but remember we subtract ~20mm for (2x) joiner section overhead

This will give something like

interior body length: |

1257mm |

side length: |

1274mm |

width at body: |

164mm |

width at headstock: |

574mm |

Cut these two pieces out, clamp together and plane edges straight and true

If there is any asymmetry, clearly mark which side is "up" on both pieces

AV-Titan corner pieces require 92mm from (outer) top of lid to bottom of lid tongue-n-groove

calculations and experience: cut the lid end-and-side pieces to be 86mm high

Since we are aiming for 215 total interior height, we have 129 left to fill.

The box sides should therefore have a height of: 118mm high

Side pieces therefore should start out as

Piece |

Number |

Size |

Lid sides |

2 |

1274 x 86mm |

Lid body end |

1 |

574 x 86mm |

Lid neck end |

1 |

164 x 86mm |

Box sides |

2 |

1274 x 118mm |

Box body end |

1 |

574 x 118mm |

Box neck end |

1 |

164 x 118mm |

In this build I could only find 6mm tongue-and-groove, and ~7mm double-angle joiner section,

so I glued strips of shim veneer to the pieces.

Experiments have proved this necessary: rivetting closes the gaps, but the resulting angle is not 90-degrees.

Don't bother on the vertical edges - angle-adjusted channel has a narrower channel.

Two options:

Mill strips to <1mm, glue and hope for the best

Mill strips to >1mm, glue, thickness with drum sander

(which is just wide enough for wide end of top & bottom(

Proposed

Simplify cutout process by making hinge, latch and handle cutouts now instead of later

After confirming these measurements, make a set of templates

Side piace cutout diagram / template |

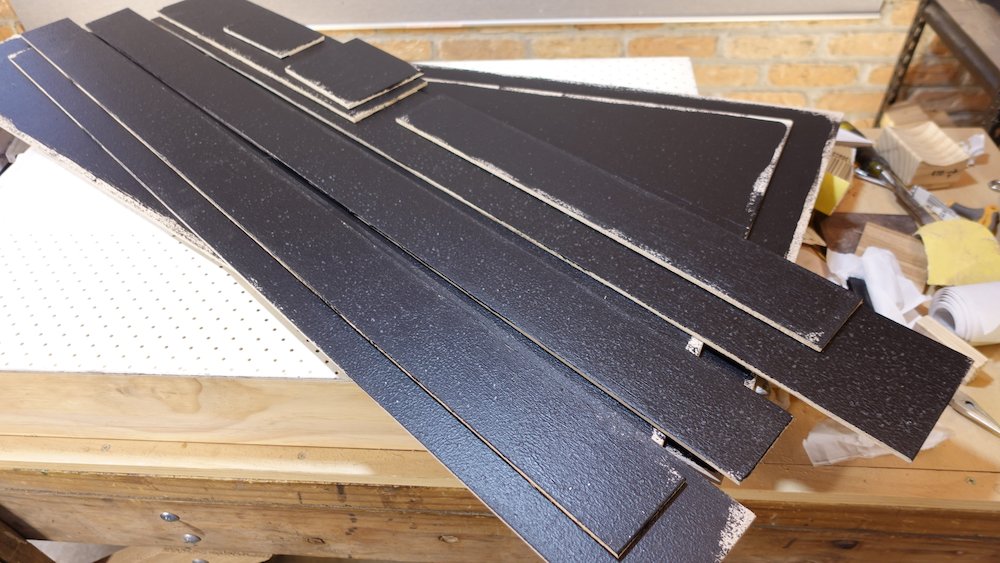

Paint the inside faces with black water-based enamel (don't need to go to the edges)

Finish the outside faces with Duratex: one brushed-on layer, one or two coarse-sponge-roller'd

To save on Duratex

Consider building neck-support piece (actual width-bevel can be finessed later)

Then we can finish the exposed parts now (see images below)

Attaching edge-padding strips |

Edge-padding strips attached |

Painted plywood pieces |

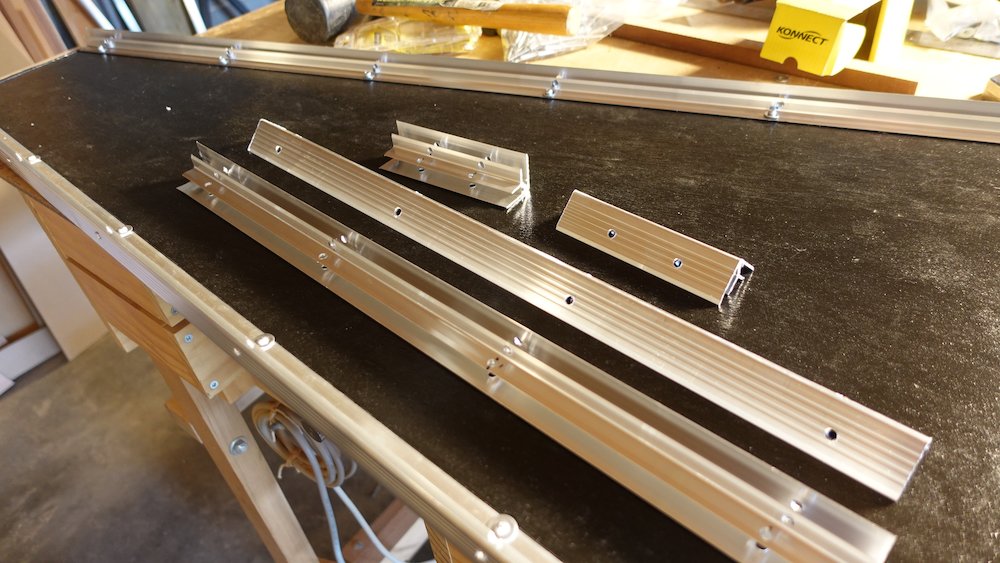

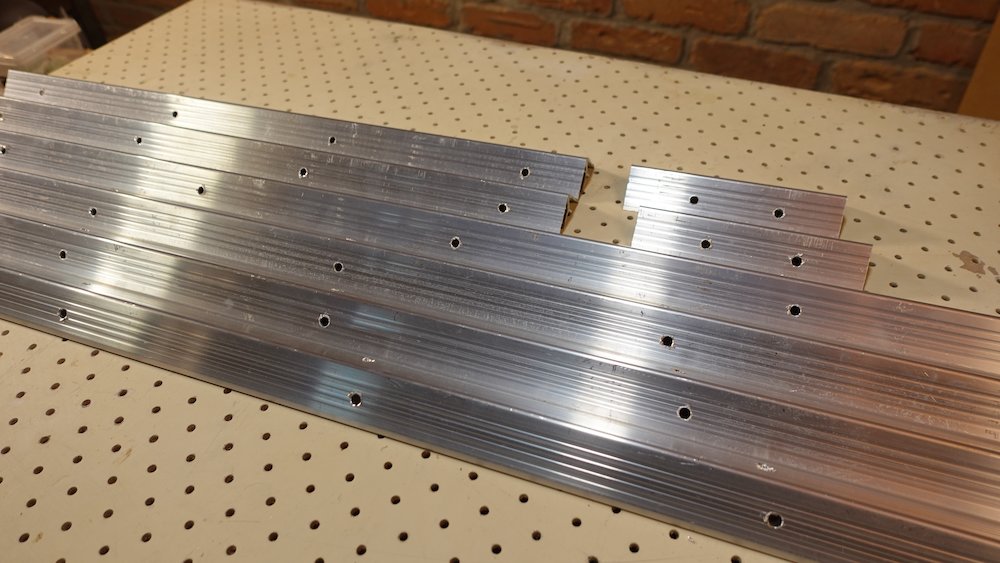

Cut pieces of angle-joiner section |

Commence construction

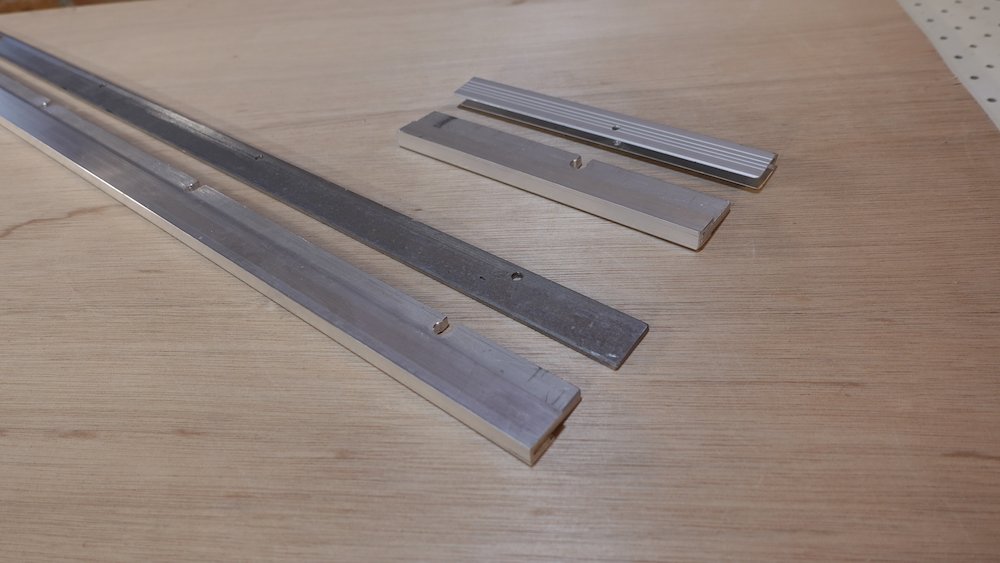

Drilling guide for double-angle joiner section

Long guide, so we can use it for hole spacing/offsetting as well as transverse position guide

Exterior piece is 3mm steel

Interior support piece is 6mm aluminium stock with cladding made from 10x20mm box section, cut lengthwise so one leg is max, the other 12mm

Drilling guide for double-angle joiner and tongue-and-groove sections

Shorter piece for drilling individual holes

Exterior piece is actually 9mm tongue-and-groove section, which allows 6mm section to nestle inside

Interiour support piece is 6mm stock with cladding from cut 10x20mm box section

The guide hole is positioned in the first narrow valley of the short leg of the 9mm section

Drilling guide pieces |

End view of support pieces |

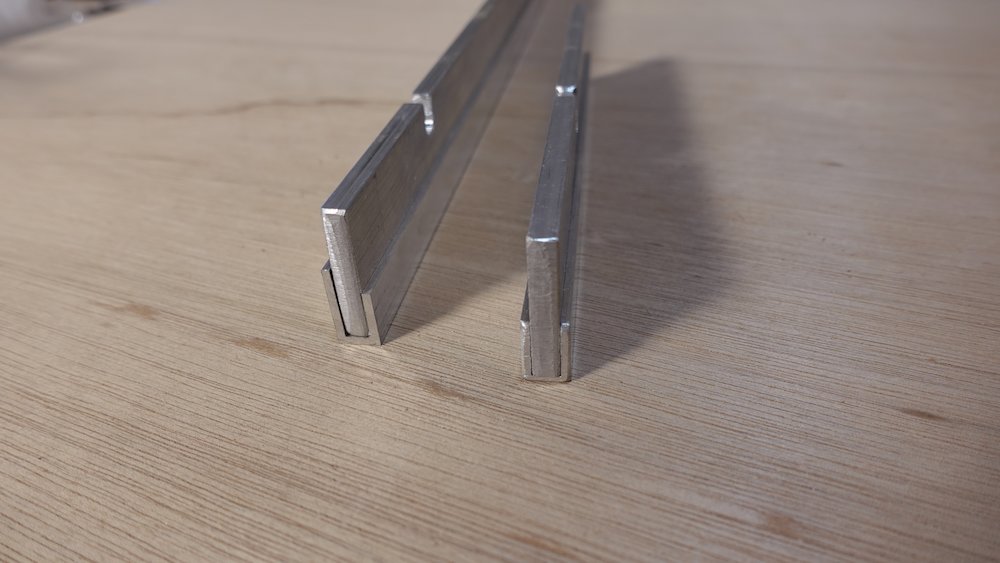

Stock loaded into drilling guides |

End view of loaded drilling guides |

Cut long lengths of double-angle joiner 40mm short of trapezoid pieces (to leave 20mm clear each end: ~1234mm)

With double-angle joiner we cannot have rivets at the same position opposing each other

we must either offset them minimally (5mm) or in some sort of alternating arrangement

for seven rivets each side, ending ~40mm in from each end of cut aluminium (~60++ in from trapezoid piece ends)

7 rivets = 193 spacing

Drilling technique:

drilling will tend to enlarge template holes

use template to drill starter holes only

when a piece or set is done, drill all the way through using internal support piece only

Follow same procedure for trapezoid end edges

channel 40mm shorter than edge (~534 & 124mm)

rivets starting 35..40mm in from edge, each pair offset by 5mm

The following measurements from LHS edge give decent offsetting:

wide end: 40, 190, 340, 490

short end: 35, 85

Attach all perimeter channel lengths to trapezoid pieces (including rivetting)

Cut corner-edge lengths for verticals

Lid: 4x 61mm

Base: 4x 94mm

Use the spreading and smooshing jigs to fit the +9/-9 degree trapezoid angles

Put some plywood scrap in the channels to assist in distributing from one side of channel to the other

Note that for spreading, some additional padding will be needed to transfer jig geometry to piece

Also, for smooshing, the jig will damage the aluminium finish, this can be legitimised by sanding and filing

Joiner section pieces drilled |

Vertical joiners spread and smooshed |

Mallet in all side pieces but don't drill through the corner-channel holes yet

Hammer in the angle-adjusted vertical channels from the open end

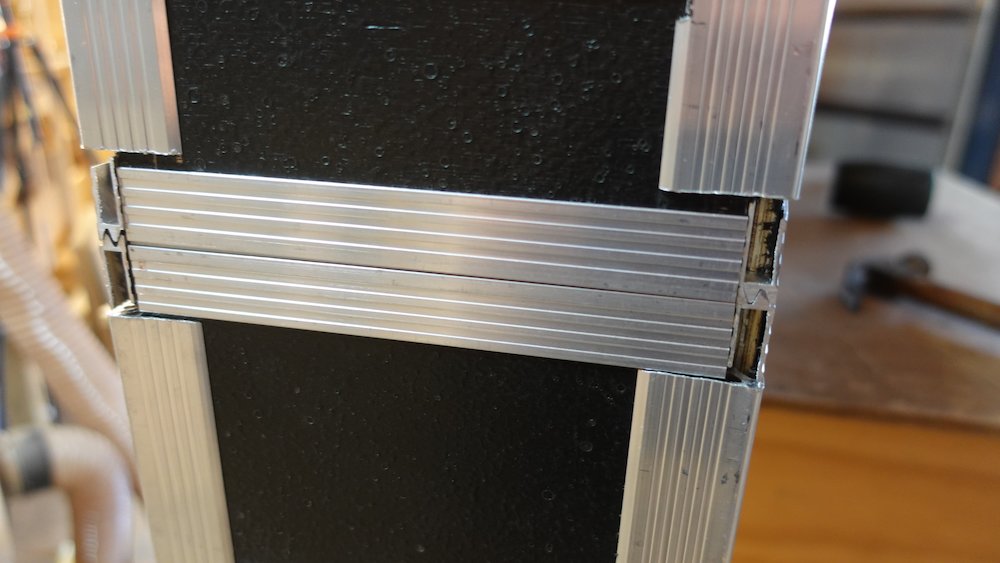

Cut tongue-and-groove channel pieces, bevelling ends with band sander, mallet them in place

Sequence

Cut the four long lengths a few mm oversize

Mallet them in place

Position lid on top of box

Slide/adjust so that lid is mating perfectly with base

Measure the two end lengths, taking note that the bevels are internal

Do the bevels on the band sander, hammer them in place

Check that lid fits

Mark external bevels on the (still oversize) but don't sand them yet

Mark all tongue-and-groove channel pieces so we know where they go, and drill rivet holes

Lid, front side:

Two, 530mm in from each end (corner brackets & latches will provide the rest)

Base, front side:

One, 530mm in from left/headstock end (ditto plus handle)

Base and lid, back side:

Two, 380mm in from each end (corner brackets and the three hinges will provide the rest)

Base and lid, wide end:

Two, 200mm in from each end

Base and lid, narrow end:

(nothing, corner brackets are enough)

Refit the tongue-and-groove pieces, clamp up, make sure everything is fully seated

Drill all holes through the wood

Drill a one or two pilot hole for four of the eight lip-corner braces (eg, all the lid pieces)

Unclamp, take off lid, rivet remaining double-angle and tongue-and-groove channel holes

Fit corner braces with single pilot rivet, reclamp, drill remaining corner brace holes, rivet

Clamp again, drill four pilot holes for remaining corner braces (nestle them against the rivetted ones in the lid)

Unclamp, rivet, clamp, drill remaining holes, unclamp rivet

Moment of truth: check that the lid fits!

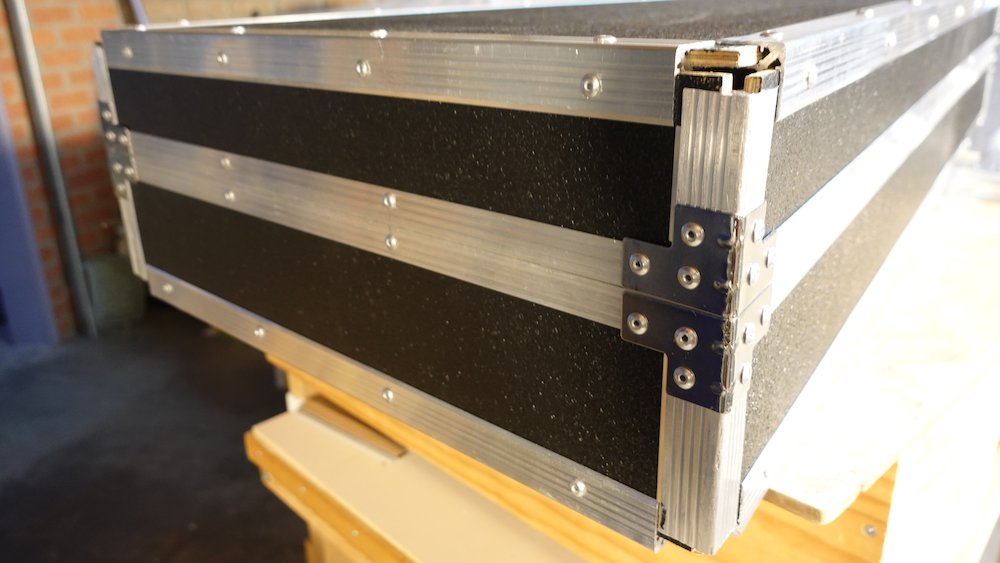

Sides assembled |

Checking alignment |

Fit corner pieces:

Assuming the pieces are correctly angle-adjusted:

Drill holes while holding each piece in place

Minor "tilting" may be required, which should increase rivet tension

Rivet in place

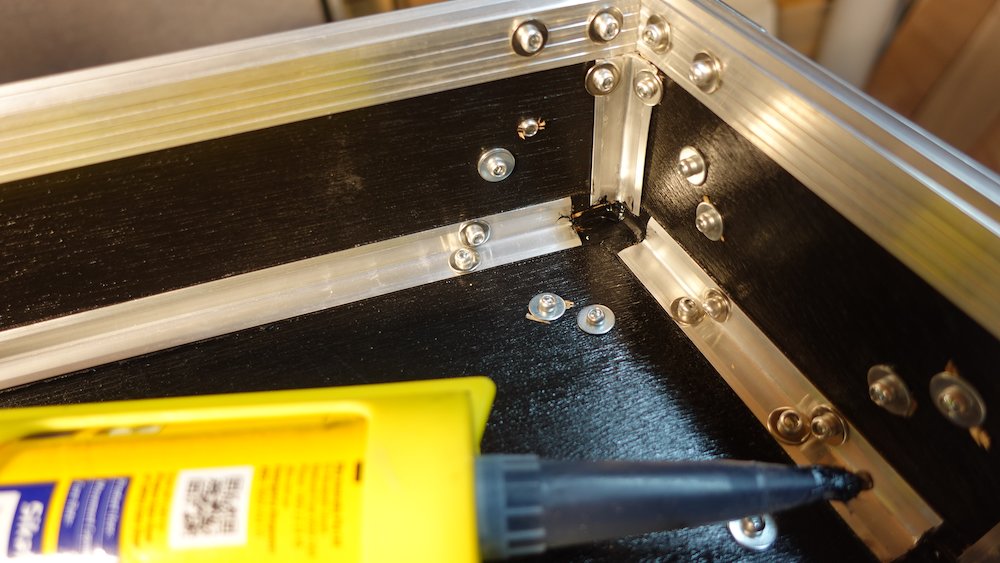

Waterproofing measures

there's quite the gap around each corner, and the 3-way corner pieces aren't a watertight fit

glue-gun some silicone sealer into corner cavity (black Sikaflex) to improve water resistance

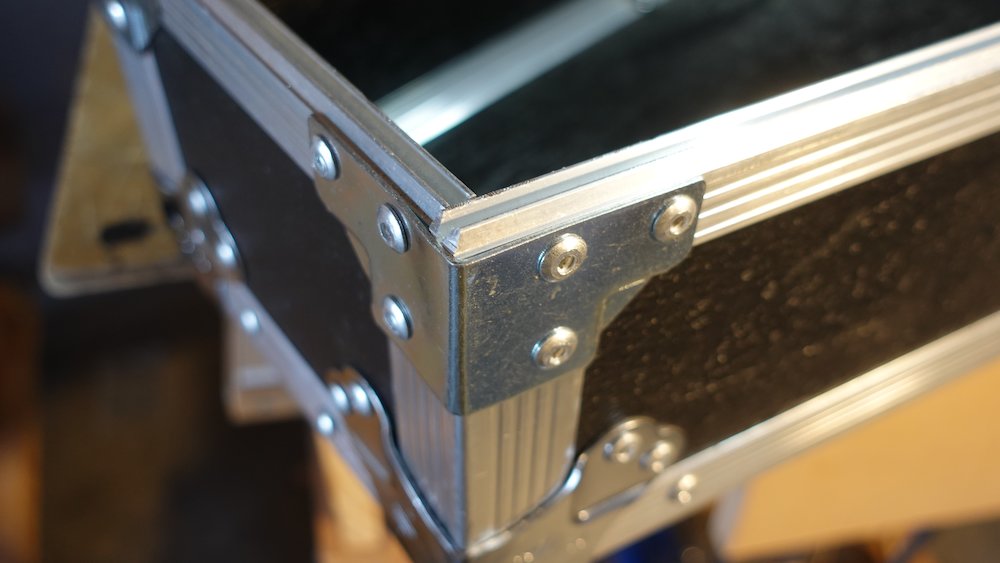

Brackets fitted |

Sealing interior corners |

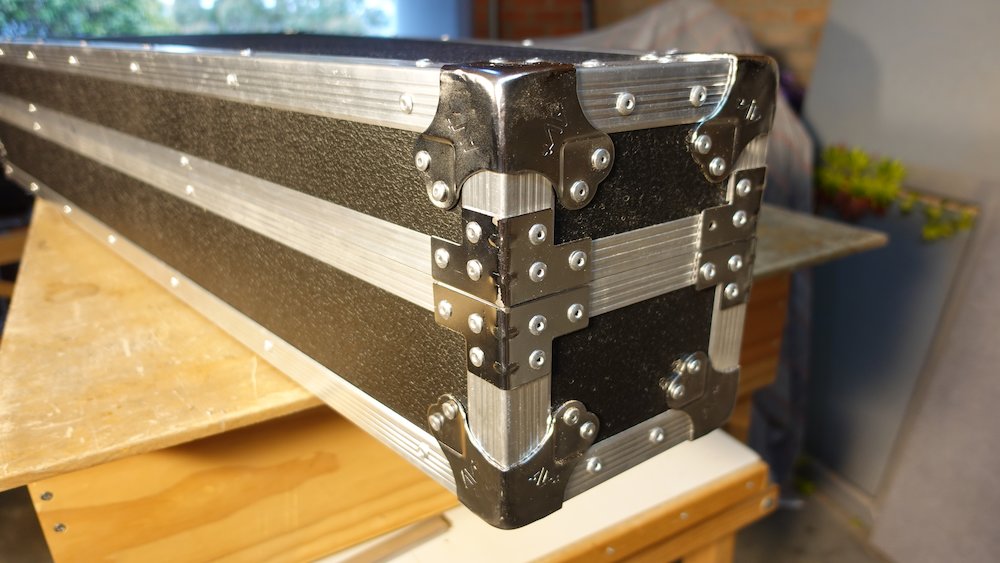

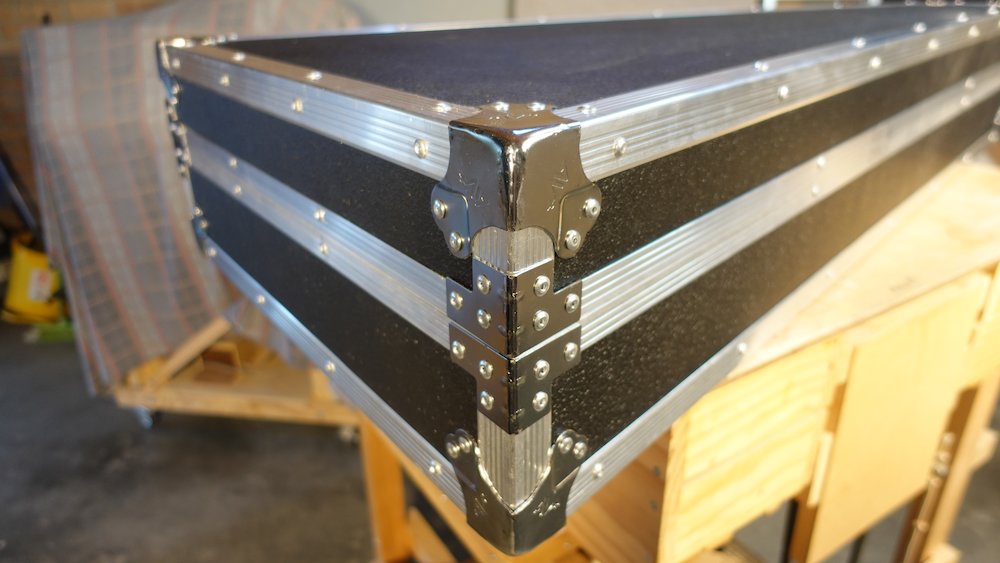

Completed corners, headstock end |

Completed corners, body end |

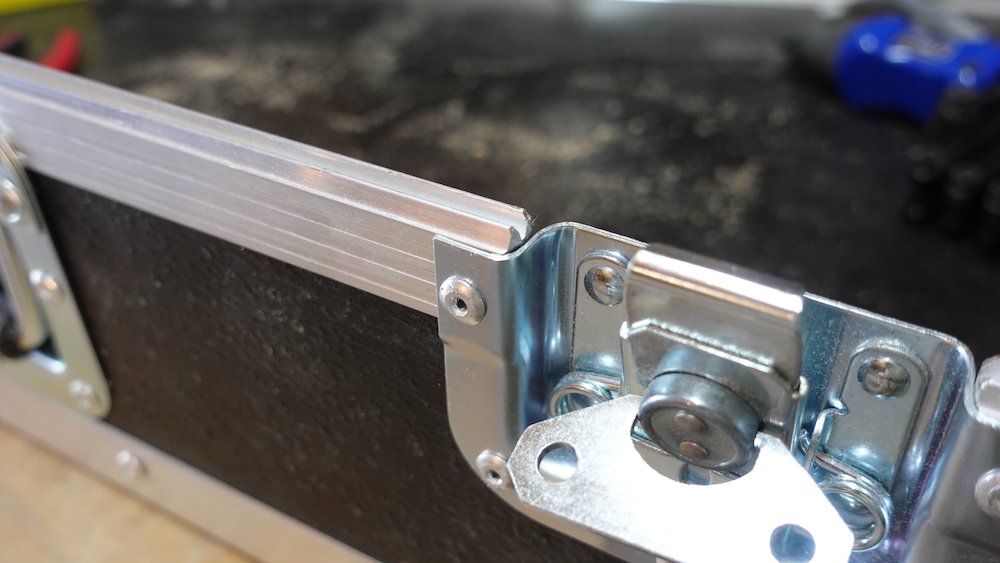

Hinge and latch cutouts

Time to cut and drill for hinges, but do not attach yet

We're using three, so the hinge-stay stresses are borne right next to the corner brackets

The two outer ones are as close as possible to the edge (leave 5mm gap from bracket)

The one in the middle is a potential problem, as it is right where we need the heel-barrier to be,

which also functions as a through-brace giving support to the handle.Therefore, the middle one should sit 530..630mm measured from the wide-end outer corner

(symmetry is overrated, lol)Current hardware:

Width |

102mm |

Cutout width |

73mm + bevel |

Cutout depth (lid) |

24mm + bevel |

Cutout depth (box) |

50mm + bevel |

Cutout depth (non-offset) |

37mm + bevel |

Surround offset |

14mm |

NB: cutout depth for box is measured from the tongue-and-groove outer-ledge, not the highest point!

Start cutout so that entire 18mm in from ends of corner brackets

Start smaller, enlarge by bevelling

Procedure:

Drill corners

Cut aluminium with angle grinder, finish with hacksaw

Cut verticals with pull-saw

Rough-in horizontals with jig-saw

Smooth aluminium with rasp

Smooth wood and enlarge/bevel to fit with Shinto saw-rasp

Again, do not attach yet

Repeat similar procedure for latches:

Current hardware same dimensions as latches

However, we only fit two, cutouts starting 250mm from each end

Don't fit them yet, the holes will make fitting hingers a lot easier

And finally again for the handle:

Centre hole approx 763mm / 537mm in from the neck/tail ends respectively

Vertical placement: align the top of the cutout with the bottom of the tongue-and-groove channel

Current hardware, hole should be 125 x 70mm

That means hole should extend from 20mm..90mm above top of bottom channel

Cut hole a little small, enlarge with file/shinto to get perfect position

Might as well fit it at this stage

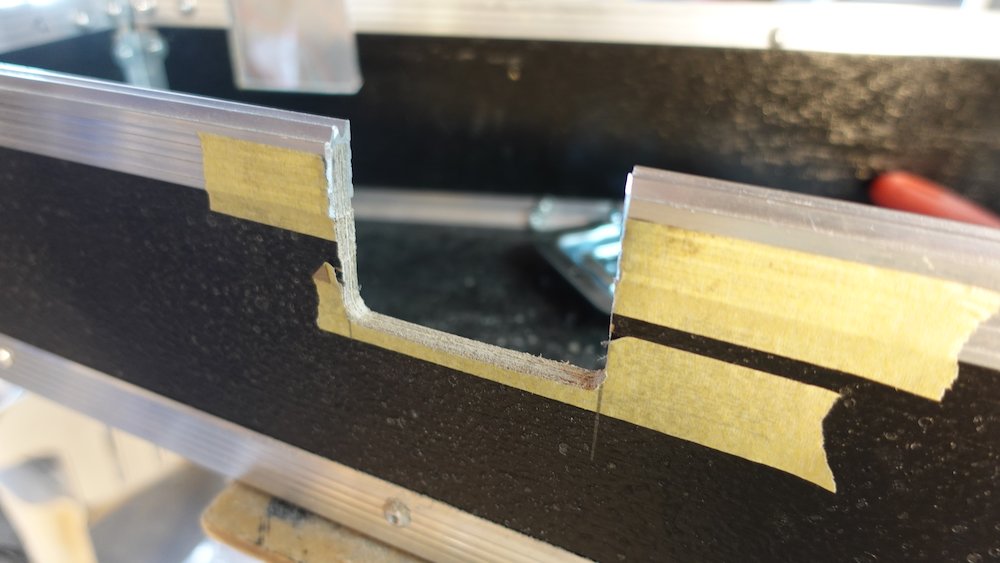

Corners |

Cutout |

Holes cleaned up, front |

Holes cleaned up, back |

Bevelled lip ends |

More bevelled lip ends |

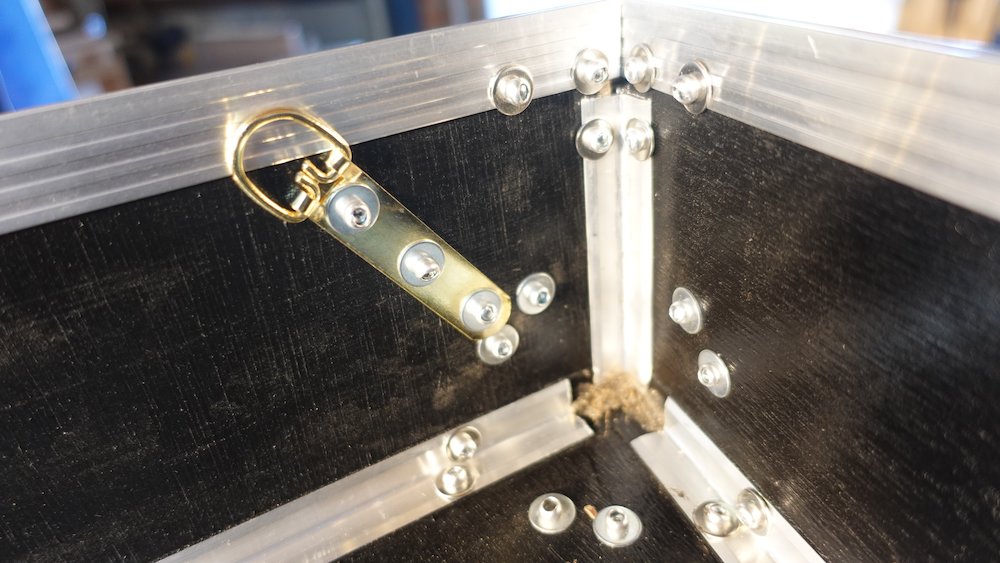

Fit anchors for cord-lid-stay (fit heavy-duty picture anchors with rivets)

Lid: approx 80mm from inner RH-front corner

Base: approx 60mm from inner RH-front corner

Cord stay anchor (lid) |

Cord stay anchor (base) |

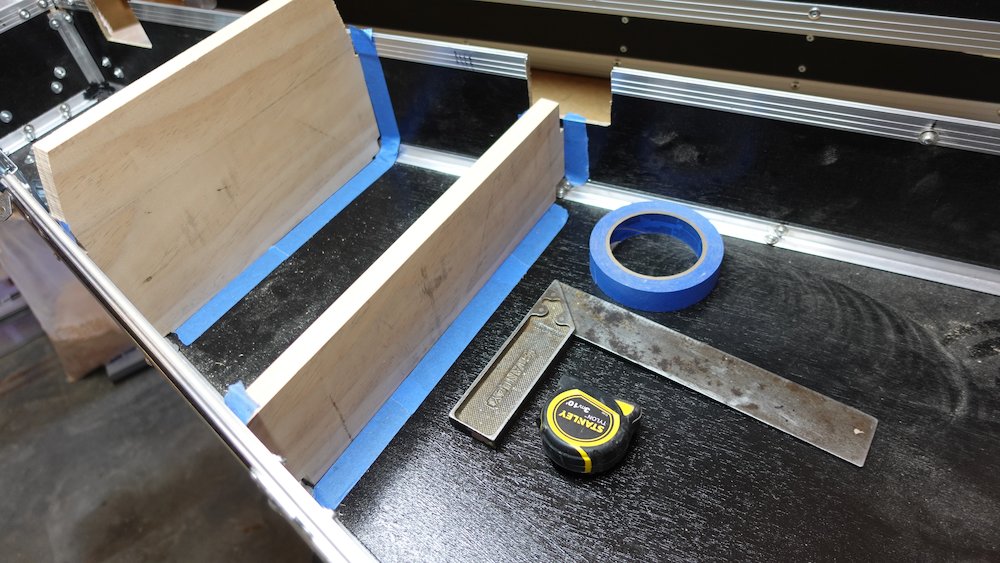

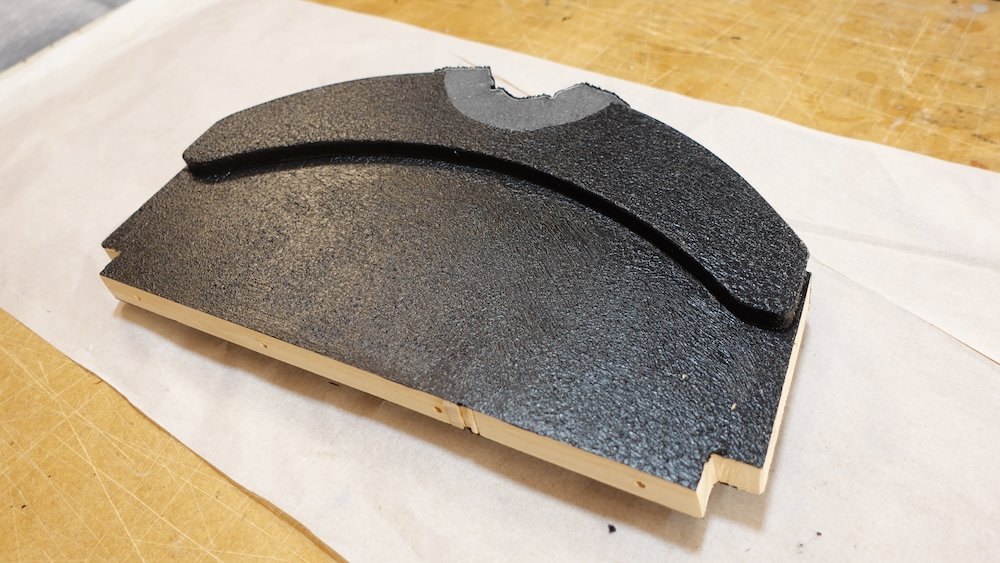

Making the heel-barrier

Cut heel-barrier timber, ~370 x 100, with bevelled sides so it fits upright

Inward-facing edge about 625 from inside of wide end.

(This would have been where the middle hinge sat, had we centred it prefectly)

Cut 16x16 cutouts in the bottom corners, to avoid aluminium channel and rivets

Cut bevel on tablesaw, with about 50mm rise over 300mm

finalise fit, making sure that piece is perpendicular to centreline

check that we're not making sides bow outward (interfering with lid closing)

However, since we'll be screwing the piece in, we don't want it pulling the sides inwards either

mark outlines on bottom and sides

drill screw holes from inside, countersink from outside

holes are best positioned if drilled from the inside,

however this can cause a lot of unwanted blowout on the other (already painted) side.

Either use a sacrificial backing piece, touch-up the blowout with paint,

or attempt to transfer measurements to the outside and drill inwards.don't screw or glue it in yet

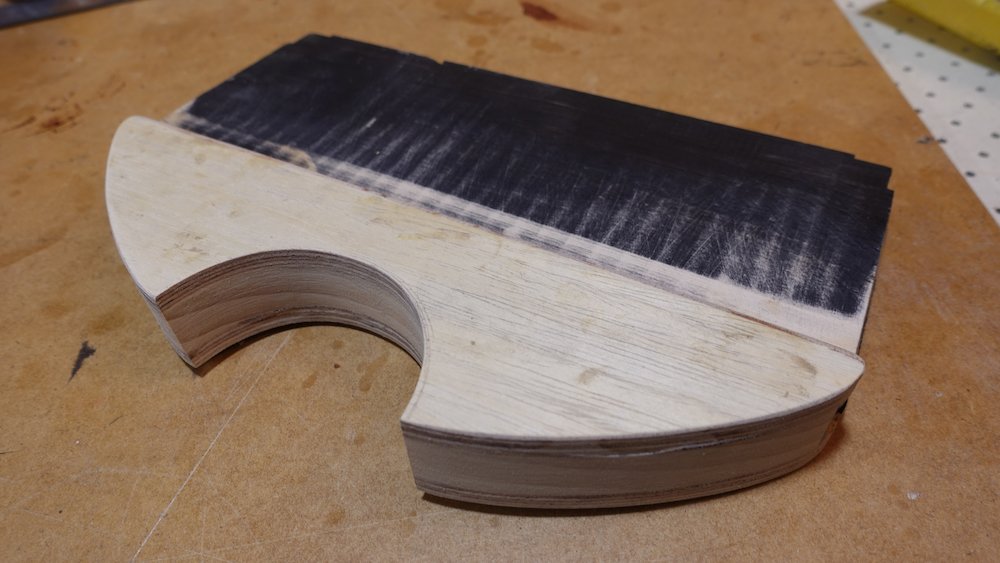

Starting the neck-support piece

Cut neck-support piece using same plan, but don't finalise height yet

190mm tall in the middle, height/shape to be finalised later

Width to fit 200mm tailward of heel-barrier cushion piece (310++mm a good start?)

At edges, trim so it clears tongue-and-groove channel

again, don't fit it!

Starting on the cushions

When attaching velvet to foam:

adhesive overspray is impossible to cleanly remove from foam

mask off any foam surface that will be exposed

Cut main base body cushions

25mm foam, use trapezoidal template, extending 540mm from tail toward heel

will stop short, to be filled in with thicker piece after fitting heel-barriercut a piece of velvet slightly overside, glue together, trim fabric flush

Cut two base tail cushions, and two base lower bout cushions

25mm foam, ~282mm long, 105-110 high

2* the harder stuff (tail) and 2* normal (lower bout)

cut maching pieces of velvet

all pieces have wrap over the top

for tail cushions, also wrap over the inner join, so strap button won't catch on trimmed edges

Cut heel-barrier cushion

harder foam, about 280x380, to wrap around the heel-barrier timber, edges flush with base

mask off barrier base and sides to prevent glue residue (which will interfere when we attach it)

attach form, trim to fit, then wrap with velvet & trim again

Nestle all pieces (so far) in place, measure and cut the tree thicker cushions

1x heel-base cushion, approx 400x70mm (bevelled to fit)

2x upper bout cushions, will be approx 300x105, with a cutout to clear the heel base cushion

cover with velvet

Completing the neck-support piece

Nestle all pieces in place again, plan height of neck-support

put guitar in padded case bottom, check neck is horizontal

put a padded shim under headstock headstock if required

measure from base to underside of neck (expect approx 170mm)

transfer this measurement to neck support piece

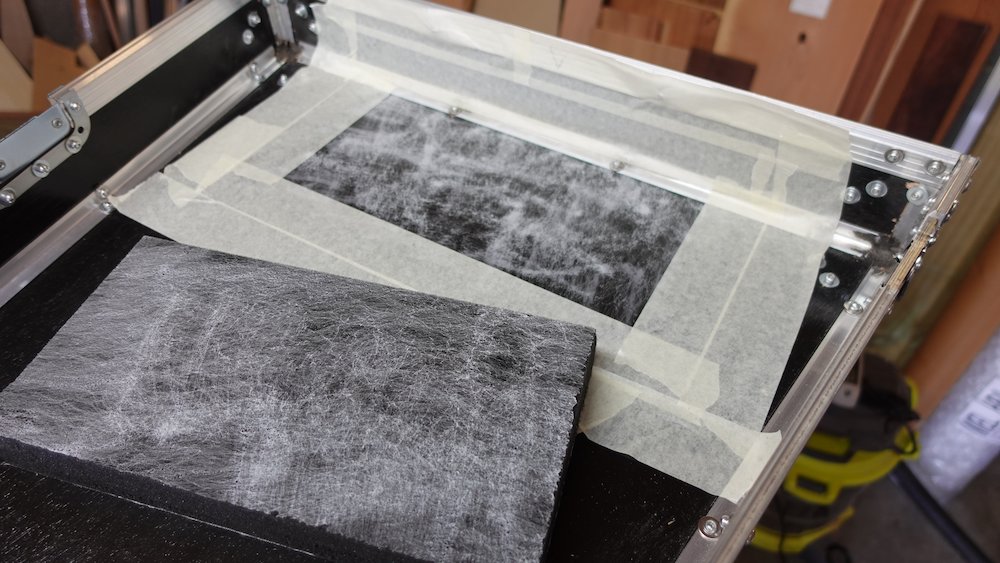

Designing neck-channel profile (see image below)

mark actual position of neck-bottom on fitting, but oncomplete neck support piece

centre this, then mark 23mm (25mm foam, slightly compressed) below that

draw a 50mm radius / 100mm diameter circle that touches this point, above it

mark a point 42mm above the lowest point of the circle

using a 13" or 14" cymbal as a guide, trace from sides to this 42mm point

the larger circle should extend up from the edge of the case bottom

the smaller circle should cut into the larger (when padded with foam, it is the neck pocket)

cut just outsite these lines roughly on the band saw, get closer on the band sander

Completing neck-channel support piece

trace the outline on some pieces of plywood, so channel portion will be thicker

decide how far these widening pieces go down: flat, aligned with tongue-and-groove, scalloped upwards, etc

cut the extra pieces, glue to main piece

finalise profile with band sander spindle etc

paint the piece black: textured finish on exposed surfaces

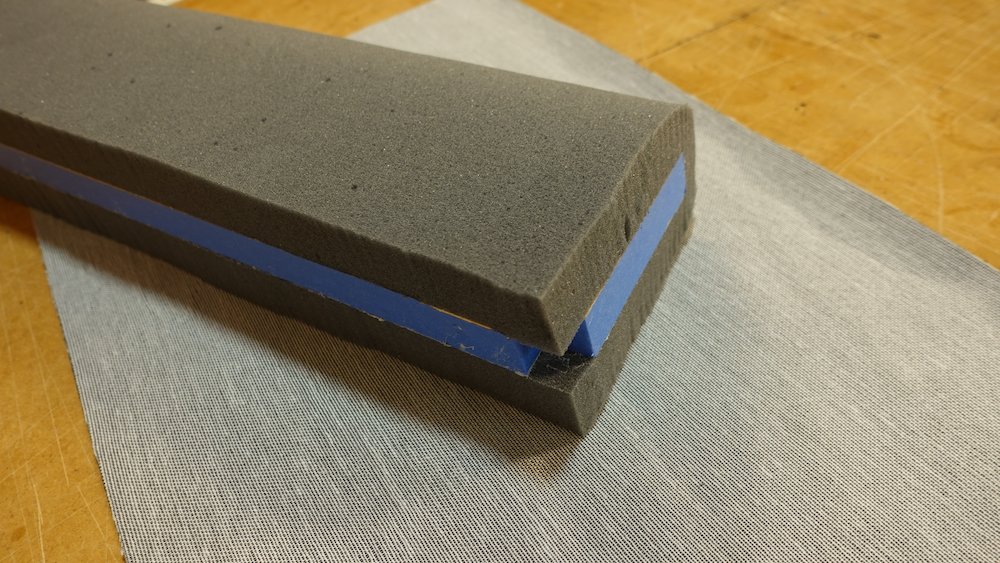

glue 25mm foam in channel

glue velvet over exposed foam channel faces

trim edges

optional: consider fabric across entire top surface?

Nestle completed neck-support in place, check strings are level lenghth-wise

hopefully, strings section will have correct clearance for 25mm foam

Fitting supports |

Gluing velvet |

Tail cushion fold-over technique |

Tail cushion before secondary gluing |

Heel stop before velvet |

Completed heel stop |

Neck-support before cushion |

Neck-support complete |

Scalloped neck support mid progress |

Scalloped neck support completed |

Lid cushions

Cut, measure, and resaw to correct thickness

one 25mm piece, 900x90mm (bridge to nut)

cut three 50mm pieces, 150x300mm, two positioned either side of strings, one between bridge and tail

They will almost certainly be too thick: rest lid in place, measure how far off closing the lid is, then resaw to correct thickness with bandsaw!Cover with velvet, glue into the lid using low-tack masking tape to protect borders from overspray

Do a test-fit of both heel-barrier and neck-support pieces

screw them in, then test that the box-sides are neither pushed out or pulled in

this can affect whether the lid closes cleanly

shim or shave accordingly

If they don't interfere with hinges, leave them screwed in, otherwise remove

Final steps

Confirm that anchors for cord-lid-stay are installed

Fit neck-support and heel-barrier pieces

Glue and screw to set

double-check how the lid closes again

Fit hinges, permanently attaching lid

Make sure cutout bevels allow the hinge to seat perfectly, and stand-offishness will prevent the lid from closing

attach to lid first, then clamp lid to base and tight before rivetting

Being able to poke your hands through the latch cutouts makes this a lot easier than if we'd already fitted latches

Fit latches

At last...

Glue in all body cushions

do any final black paint touch ups if required, inside and out

Fit cord-lid-stay (the cord part)

Attaching cushions |

Lid cushions fitted |

Completed case |

Completed case |

Completed case with occupant |

All content Copyright 20xx Trevor Magnusson

| × | |